Best-Selling Sinter Plate Filter Media - Delta2type-Sinter Plate-Sinter Plate Filter-Sinter Plate Filter Media-Herding Sinter Plate Filter – Sinter Plate

Best-Selling Sinter Plate Filter Media - Delta2type-Sinter Plate-Sinter Plate Filter-Sinter Plate Filter Media-Herding Sinter Plate Filter – Sinter Plate Detail:

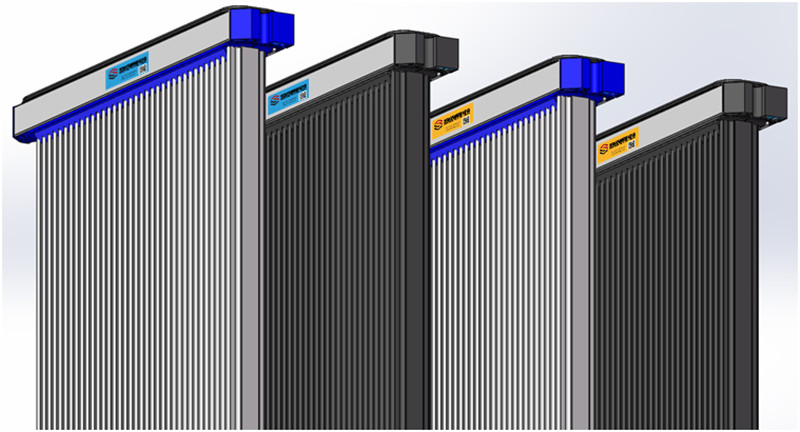

The lastest type of Sinter Plate Filter Element (recommended): Delta2 Series

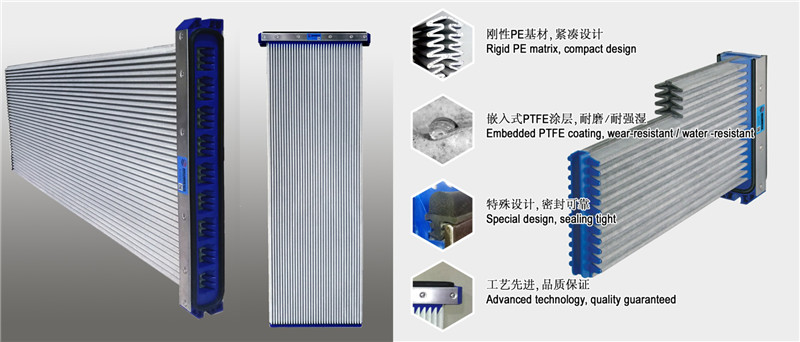

Germany Originated + Imported Materials + Technology Innovation Certified by German laboratory. The base body (rigid) is sintered plate with hydrophobic PTFE coating which is securely embedded in the base body. With it’s special features of DELTA² filters ,it can be installed not only in vertical arrangement on both the raw gas and clean gas side but also in horizontal arrangement .

The lastest type of Sinter Plate Filter Element (recommended):

Delta2 Series

Germany Originated + Imported Materials + Technology Innovation

Certified by German laboratory.

Filter Size

| Size | Filtration Area (m2) |

| Delta2_1500 / 9 | 4.75 |

| Delta2_750 / 9 | 2.34 |

| Delta2_500 / 9 | 1.57 |

Filter Media

| Parameter Media Code |

NT1 | AT1 | NT2 | AT2 |

| Efficiency | 99.999% @ 1μm | |||

| Operation Temp. | 70℃ | 70℃ | 100℃ | 100℃ |

| Purging Air Pressure | 2.5~5.0 Bar | |||

| Electrostatic Leakage Resistance | N/A | ≤ 106Ω | N/A | ≤ 106Ω |

| A/C Ratio | 0.8~1.3 m/min | |||

| Air Resistance | 1500~2000 Pa(Depends on operating conditions) | |||

| Gasket Ring Installation Type | Raw Gas / Clean Gas | |||

* Please indicate “Size + Media Code + Gasket ring installation type” when ordering.

Example: Sinter Plate Filter Element, Type: Delta2_1500/9 NT1 (raw gas).

| 1. High filtration grade: Can deal with 0.1μm particle size.2. High filtration efficiency: 99.999% @ 1μm, emission<<1 mg/Nm3 (DMT certified).3. Super long service time: PE matrix + PTFE coating, rigid body and embedded coating which is hard to be worn or torn, performance guaranteed, and service life is expected ≥ 10 years. 4. Surface-filtration, constant resistance, design air volume is stable. 5. Discharge indoors, large energy saving, equipment investment can be recovered in 2~3 years. 6. PE and PTFE material, strong acid, alkali and humidity resisting. 7. Washable, repairable; 8. Fiber free, lint free, environmental-friendly materials, no pollution to products (FDA Compliant). 9. PWIS-free. 10. Anti-static type available for explosive dust / gas (DEKRA certified). |

|

Ideal choice for ultrafine powder recovery or wearing dust capture !

Gasket Ring Installation Type

Raw gas installation(Gasket on front side of head) Vertical filter housing, maintenance carried out in dirty area. |

Clean gas installation(Gasket on back side of head) Horizontal filter housing, maintenance carried out in clean area. |

| Steel Industry | Nonferrous Metallurgy | Automobile Industry | Ore Processing | Rubber Tyre Industry |

| Electronics Industry | Foundry | Laser-Cutting | Chemical Industry | Pharmacy |

| Food Processing | Glass and Ceramics Industry | Cement and Lime Industry | Metal Work | … |

Product detail pictures:

Related Product Guide:

Cooperation

We also offer product sourcing and flight consolidation services. We have our own factory and sourcing office. We can provide you with almost every type of product related to our product range for Best-Selling Sinter Plate Filter Media - Delta2type-Sinter Plate-Sinter Plate Filter-Sinter Plate Filter Media-Herding Sinter Plate Filter – Sinter Plate , The product will supply to all over the world, such as: Philadelphia , Uruguay , United Arab Emirates , The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.