Factory Directly supply China High Quality Ceramic Filter Plate for Refining Machine

We aim to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for Factory Directly supply China High Quality Ceramic Filter Plate for Refining Machine, If you are fascinated in any solutions, you should experience absolutely free to make contact with us for additional details or you should send out us email instantly, we will reply you within just 24 hours and also the best quotation might be provided.

We aim to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for China Creamic Fiflter Plate, china Plate Filter, Plate Filter factory, Plate Filter manufacturer, Plate Filter supplier, Refining Melting Machine, Only for accomplishing the good-quality product to meet customer’s demand, all of our products and solutions have been strictly inspected before shipment. We always think about the question on the side of the customers, because you win, we win!

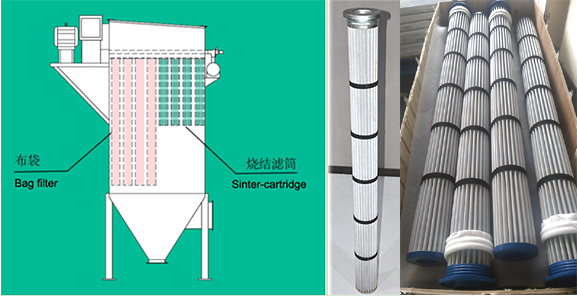

Combining the revolutionary materials of dry-filtration technology with bag filters: Sinter Cartridges. PE (polyethylene) porous matrix and PTFE embedded coating, pure surface filtration, efficient wear-resistant sinter plate filtration media with the wave-shaped cylindrical structure, the perfect alternative to bags and its cage.Using bag filter, it has the problems of discharge over standard, deducting air volume decreased and changing cloth bag frequently,ect. Through the simple and easy -to-use sinter cartridge, it is easy to solve these difficult problem.

Whether it is the dust with strong abrasion, or the ultra-fine dust, or even the wet working condition, the sinter-cartridge can handle it calmly.

For bag filter upgrade at minimum cost:

Sinter-Cartridge: LT Series

|

Reduce downtime.Reduce operation cost.Meet emission standards.Maximize dust collector capacity.Prolong dust collector service life. |

| Is the old bag filter not easy to use? | Does your bag filter discharge over standard? Has the dedusting air volume decreased significantly? Do you need to change cloth bags frequently? | We provide you with the appropriate solution, through the simple and easy-to-use sinter-cartridge, to solve your difficult problems. |

| Combination of revolutionary dry filtration technology material and bag filter: sinter-cartridge | PE porous matrix + PTFE embedded coating, pure surface-filtration, high-efficiency and wear-resistant sintered filter media, with wave shaped cylinder structure, perfectly replacing the cloth bag and cage; | 99.999% efficiency.Dealing with 0.1um particle.Emission<< 1mg / Nm3Self lubricating and hydrophobic material, easy to purgeNo fiber |

| Significant improvement in service life and efficiency | Whether it is the dust with strong abrasion, or the ultra-fine dust, or even the wet working condition, the sinter-cartridge can handle it calmly. | The sinter-cartridge made of advanced sintered filter media, which has high filtration efficiency, service life expectancy of more than 10 years, and consistent filtration performance. |

| Low cost, fast and simple | Select the sinter-cartridge and replace the bag filter directly without changing the structure of the original dust collector. | Reduce downtime, prolong dust collector service life. |

Filter Size

|

Size |

Filtration Area (m2) |

| LT125-1500 |

1.49 |

| LT125-750 |

0.73 |

| LT125-500 |

0.48 |

| * LT133-1500 |

1.62 |

| * LT133-750 |

0.80 |

| * LT133-500 |

0.53 |

| LT162-1500 |

2.03 |

| LT162-750 |

1.00 |

| LT162-500 |

0.66 |

* Recommended type. (Other types not on list can be customized.)

Filter Media

| Parameter Media Code |

NT1 |

AT1 |

NT2 |

AT2 |

| Efficiency: 99.999% @ 1μm |

● |

● |

● |

● |

| Operation Temp. |

70℃ |

70℃ |

100℃ |

100℃ |

| Electrostatic Leakage Resistance |

N/A |

≤ 106Ω |

N/A |

≤ 106Ω |

| A/C Ratio |

0.8~1.3 m/min |

|||

| Air Resistance |

1500~2000 Pa (Depends on operating conditions) |

|||

| Gasket Ring Installation Type |

Clean Gas |

|||

* Please indicate “Size + Media Code” when ordering.

Example: Sinter-cartridge, Type: LT133-1500 NT1.

| Steel Industry | Nonferrous Metallurgy | Automobile Industry | Ore Processing | Rubber Tyre Industry |

| Electronics Industry | Foundry | Laser-Cutting | Chemical Industry | Pharmacy |

| Food Processing | Glass and Ceramics Industry | Cement and Lime Industry | Metal Work | … |

-

Sinter-Cartridge Filter Element (LT Series)

Sinter-Cartridge Filter Element (LT Series)