Kartridge-Sinter Plate Filter-Sinter saxan ururiyaha siigada

Sharaxaada soo saarista

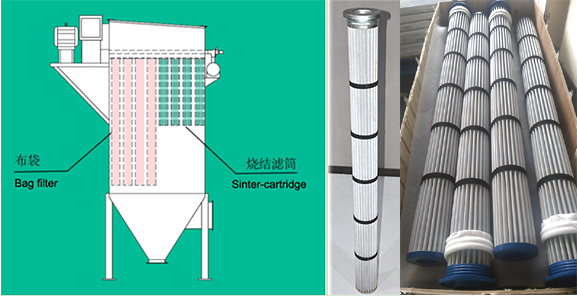

Isku darka walxaha kacaanka ee tiknoolajiyada sifaynta qalalan ee bacaha shaandhada: Sinter Cartridges.PE (polyethylene) matrix dalool ah iyo PTFE daahan gundhig, sifaynta dusha saafi ah, hufnaan xirashada u adkeysiga sinta saxan saxan warbaahinta qaab dhismeedka cylindrical mawjada-qaabeeya, beddelka ugu fiican ee bacaha iyo qafis ay.Isticmaalka shaandhada bacda, waxa ay leedahay dhibaatooyinka dheecaanka dheecaanka. in ka badan heerka caadiga ah, hoos u dhac ku yimid mugga hawada iyo beddelka bacda marada si joogto ah, ect.Iyada oo loo marayo kartoon fudud oo si sahlan loo isticmaali karo sinter, way fududahay in la xalliyo dhibaatadan adag.

Haddi ay tahay boodhka leh nabarada xooggan, ama boodhka aadka u fiican, ama xitaa xaaladda shaqada ee qoyan, sinter-cartridge ayaa si deggan u xamili kara.

Tilmaamaha/Faa'iidooyinka

cusboonaysiinta shaandhaynta bacda qiimaha ugu yar:

Sinter-Cartridge: Taxanaha LT

| Iska yaree wakhtiga dhimistaIska yaree kharashka hawlgalkaLa kulan heerarka qiiqa.Kordhi awoodda boodhka ururiyahaKordhi nolosha adeegga boodhka ururiyaha. |

| Shaandheeyaha bacdii hore ma fududa in la isticmaalo? | Boorsadaadu miyay ka miiraysaa dareeraha heerka caadiga ah?Mugga hawada wasakhaynta miyuu si weyn hoos ugu dhacay?Ma u baahan tahay inaad si joogto ah u beddesho bacaha marada? | Waxaan ku siinaynaa xalka ku habboon, iyada oo loo marayo sinta-kartridge fudud oo si sahlan loo isticmaali karo, si loo xalliyo dhibaatooyinkaaga adag. |

| Isku darka kacaanka Qalabka tignoolajiyada sifaynta qalalan iyo shaandhaynta bacda: sinter-kartridge | Matrix PE-dabool + PTFE daahan gunaysan, sifaynta dusha saafiga ah, hufnaanta sare iyo xidhashada u adkaysta warbaahinta shaandhaynta, oo leh qaab-dhismeedka dhululubada mawjada qaabaysan, oo si fiican u beddelaya bacda marada iyo qafiska; | 99.999% hufnaan. Wax ka qabashada 0.1um qayb ka mid ah3Saliid-is-daynta iyo walxaha hydrophobic, oo ay fududahay in la nadiifiyo No fiber |

| Horumar la taaban karoadeegnolosha iyo waxtarka | Haddi ay tahay boodhka leh nabarada xooggan, ama boodhka aadka u fiican, ama xitaa xaaladda shaqada ee qoyan, sinter-cartridge ayaa si deggan u xamili kara. | Kartridge-ka-kartridge-ka laga sameeyay warbaahinta shaandhaynta sareeysa, kaas oo leh hufnaanta sifeynta sare, rajada nolosha adeegga in ka badan 10 sano, iyo waxqabadka sifeynta joogtada ah. |

| Qiime jaban, degdeg ah oo fudud | Dooro kartridge-ka oo si toos ah u beddel shaandhada bacda adoon beddelin qaab-dhismeedka boodhka ururiyaha asalka ah. | Iska yaree wakhtiga dhimista, sii kordhi nolosha adeegga boodhka ururiyaha. |

Xogta Farsamada

Cabirka Shaandhaynta

| Cabbirka | Aagga sifaynta (m2) |

| LT125-1500 | 1.49 |

| LT125-750 | 0.73 |

| LT125-500 | 0.48 |

| * LT133-1500 | 1.62 |

| * LT133-750 | 0.80 |

| * LT133-500 | 0.53 |

| LT162-1500 | 2.03 |

| LT162-750 | 1.00 |

| LT162-500 | 0.66 |

* Nooca lagu taliyay.(Noocyada kale ee aan liiska ku jirin waa la beddeli karaa.)

Shaandhee Media

| Halbeegga Xeerka Warbaahinta | NT1 | AT1 | NT2 | AT2 |

| Waxtarka: 99.999% @ 1μm | ● | ● | ● | ● |

| Heerkulka Operation | 70℃ | 70℃ | 100 ℃ | 100 ℃ |

| Iska caabinta dheecaanka Electrostatic | N/A | ≤ 106Ω | N/A | ≤ 106Ω |

| Saamiga A/C | 0.8 ~ 1.3 m/daqiiqo | |||

| Iska caabinta hawada | 1500-2000 Pa (waxay kuxirantahay xaaladaha shaqada) | |||

| Nooca Rakibaadda giraanta Gasket | Gaas Nadiifi | |||

Fadlan tilmaan "Size + MediaKoodhka” marka la dalbanayo.

Tusaale: Sinter-cartridge, Nooca: LT133-1500 NT1.

Goobaha lagu dabaqi karo

| Warshadaha birta | Biraha aan birta ahayn | Warshadaha baabuurta | Qalabaynta macdanta | Warshadaha taayirrada caagga ah |

| Warshadaha Elektarooniga ah | Foundry | Laser-Goynta | Warshadaha Kiimikada | Farmashiyaha |

| Habaynta cuntada | Warshadaha dhalooyinka iyo dhoobada | Warshadaha sibidhka iyo lime | Shaqada Birta | … |

-

Cunsurka Shaandheeyaha-Cartridge (LT Taxanaha)

Cunsurka Shaandheeyaha-Cartridge (LT Taxanaha)