Filter ea Cartridge-Sinter Plate-Sinter Plate Collector-Herding Sinter Plate Filter-Sintered Stainless Stainless Steel Plate

Tlhaloso ea Tlhahiso

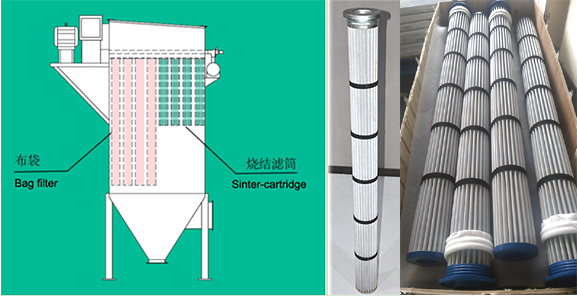

Ho kopanya lisebelisoa tsa phetoho ea theknoloji ea ho hloekisa ka mokhoa o omileng le li-filters tsa mekotla: Sinter Cartridges.PE (polyethylene) matrix a porous le PTFE e kenngoeng ka ho roala, ho hloekisa ka holim'a metsi, lisebelisoa tse sebetsang hantle tsa sinter plate filtration tse nang le sebopeho sa cylindrical se nang le sebōpeho sa maqhubu, se fapaneng le mekotla le cage ea sona. ka mokhoa o tloaelehileng, ho fokotsa molumo oa moea ho fokotsehile le ho fetola mokotla oa lesela khafetsa, joalo-joalo.Ka cartridge ea sinter e bonolo le e bonolo ho e sebelisa, ho bonolo ho rarolla bothata bona bo thata.

Ebang ke lerōle le nang le abrasion e matla, kapa lerōle le leholo haholo, kapa esita le boemo ba ho sebetsa bo metsi, sinter-cartridge e ka sebetsana le eona ka khutso.

Likarolo/Melemo

Bakeng sa ntlafatso ea filthara ea mokotla ka theko e tlase:

Sinter-Cartridge: LT Series

| Fokotsa nako ea ho phomola.Fokotsa litšenyehelo tsa ts'ebetso.Kopana le litekanyetso tsa tlhahiso.Eketsa bokhoni ba pokello ea lerōle.Lelefatsa bophelo ba tšebeletso ea mokelli oa lerole. |

| Na sefe ea khale ea mokotla ha e bonolo ho e sebelisa? | A na mokotla oa hau oa sefa o tsoa ka mokhoa o tloaelehileng?Na molumo oa moea o thellang o fokotsehile haholo?Na u hloka ho fetola mekotla ea masela khafetsa? | Re u fa tharollo e nepahetseng, ka sinter-cartridge e bonolo le e bonolo ho e sebelisa, ho rarolla mathata a hau a thata. |

| Motsoako oa phetohelo thepa ea theknoloji ea ho hloekisa e omileng le filthara ea mokotla: sinter-cartridge | PE porous matrix + PTFE e kentsoeng e kentsoeng, e hloekisang holim'a metsi, e sebetsang ka mokhoa o phahameng le e sa sebetseng ea sintered filter media, e nang le sebopeho sa cylinder e entsoeng ka leqhubu, e nkela mokotla oa lesela le cage sebaka ka ho phethahetseng; | 99.999% e sebetsang hantle.Ho sebetsana le 0.1um particle.Emission <<1mg / Nm3Lintho tse itlotsang le tsa hydrophobic, ho bonolo ho li hloekisa |

| Ntlafatso e kholo hotshebeletsobophelo le katleho | Ebang ke lerōle le nang le abrasion e matla, kapa lerōle le leholo haholo, kapa esita le boemo ba ho sebetsa bo metsi, sinter-cartridge e ka sebetsana le eona ka khutso. | Sinter-cartridge e entsoeng ka mecha ea litaba ea sintered filter e tsoetseng pele, e nang le ts'ebetso e phahameng ea ho sefa, nako ea bophelo ea ts'ebeletso ea lilemo tse fetang 10, le ts'ebetso e tsitsitseng ea ho sefa. |

| Theko e tlaase, e potlakileng le e bonolo | Khetha sinter-cartridge 'me u nkele filthara ea mokotla ka kotloloho ntle le ho fetola sebopeho sa mokelli oa lerōle oa pele. | Fokotsa nako ea ho phomola, lelefatsa bophelo ba tšebeletso ea mokelli oa lerōle. |

Lintlha tsa Tekheniki

Boholo ba Sefe

| Boholo | Sebaka sa Tlhophiso (m2) |

| LT125-1500 | 1.49 |

| LT125-750 | 0.73 |

| LT125-500 | 0.48 |

| LT133-1500 | 1.62 |

| LT133-750 | 0.80 |

| LT133-500 | 0.53 |

| LT162-1500 | 2.03 |

| LT162-750 | 1.00 |

| LT162-500 | 0.66 |

* Mofuta o khothalelitsoeng.(Mefuta e meng e seng lethathamong e ka etsoa ka mokhoa o ikhethileng.)

Sefa Mecha ea litaba

| Paramethara Mecha ea litaba Code | NT1 | AT1 | NT2 | AT2 |

| Katleho: 99.999% @ 1μm | ● | ● | ● | ● |

| Opereishene Temp. | 70 ℃ | 70 ℃ | 100 ℃ | 100 ℃ |

| Ho hanyetsa ho lutla ha motlakase | N/A | ≤ 106Ω | N/A | ≤ 106Ω |

| Karolelano ea A/C | 0.8–1.3 m/min | |||

| Ho hanyetsa Moea | 1500 ~ 2000 Pa (Ho ipapisitse le maemo a ts'ebetso) | |||

| Mofuta oa ho kenya Ring ea Gasket | Khase e Hloekileng | |||

* Ka kopo, bontša "Size + MediaKhoutu” ha o odara.

Mohlala: Sinter-cartridge, Mofuta: LT133-1500 NT1.

Libaka tse sebetsang

| Indasteri ea tšepe | Nonferrous Metallurgy | Indasteri ea Likoloi | Ts'ebetso ea Ore | Indasteri ea Lithaere tsa Rubber |

| Indasteri ea Elektronike | Foundry | Laser-Cutting | Indasteri ea Lik'hemik'hale | Pharmacy |

| Phetoho ea Lijo | Indasteri ea Khalase le Ceramics | Indasteri ea Samente le Kalaka | Mosebetsi oa Tšepe | … |

-

Sinter-Cartridge Filter Element (LT Series)

Sinter-Cartridge Filter Element (LT Series)