Sinter plate filter – HSL mofuta -Sinter Plate-Sintered Plate-Sinter Plate Filter-Plastic Sintered Plate-Sintered Plate

Tlhaloso ea Tlhahiso

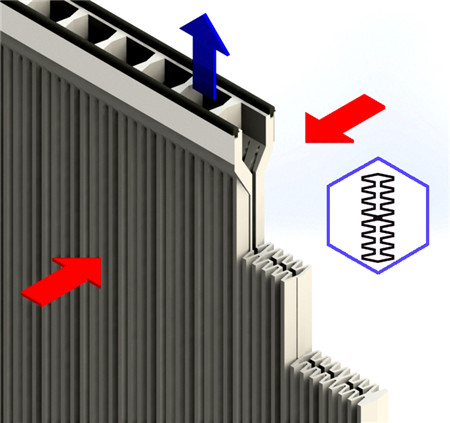

Sinter plate filter ke mofuta oa botsitso ba sebopeho le ho hanyetsa ka matla tšusumetsong le bokhoni ba ho sefa thepa.E boetse e bitsoa "plastic sinter plate".Letlapa le thata la ho sefa leo matrix a lona a entsoeng ka phofo ea PE ka mokhoa o khethehileng oa sinter, 'me a koahetsoe ka PTFE (eo hangata e tsejoang e le "Plastiki King", thepa ea ho roala ea pitsa e sa reng letho).Ka lebaka la tlhoekiso e hloekileng ea holim'a metsi, e thibela lerōle ka ntle ho lisebelisoa 'me e ka hloekisoa habonolo ka mohala.E na le ho nepahala ho matla ho hloekisa, e ka sebelisoang libakeng tse fapa-fapaneng tse phahameng kapa tse tlaase tsa mocheso, 'me e ka sebelisoa khafetsa, ka katleho e fokotsa litšenyehelo tsa tlhahiso.

Likarolo/Melemo

Mofuta oa Pele oa Sinter Plate Filter Element (Bakeng sa ho nkela sebaka):

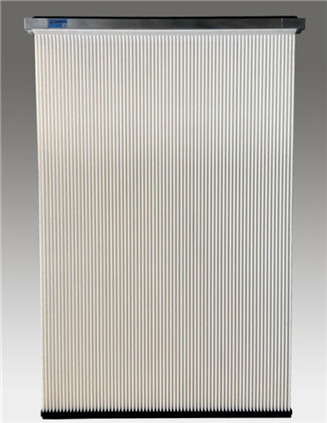

HSL_1500/18

| Joale sinter plate ke eng?Letlapa la sinter mona le bua ka poleiti e thata ea ho sefa eo matrix e entsoeng ka phofo ea PE ka mokhoa o khethehileng oa sinter, lee koahetsoeng ka PTFE (eo hangata e tsejoang e le "Plastic King", e leng thepa ea ho roala ka pitsa e sa reng letho).Hobane thepa e tala ke lipolasetiki kaofela, e boetse e bitsoa "plastic sinter plate".Theknoloji ena e simolohile Jeremane, 'me e kaetsa li-filters tse nang le libopeho tse fapaneng.PTFE barbotage ka thibela lerōle ka ntle ho filthara lintho tse bonahalang, e le phello ea "surface filtration".Sena se fapane haholo le phello ea "deep filtration" ea filthara ea fiber.Mothating ona, mecha ea litaba feela ea boemo bo holimo e ka bapisoang le poleiti ea sinter, empa ho roala ha poleiti ea sinter ho kenella botebong ba matrix, 'me ha ho bonolo ho apareloa le ho taboha, hammoho le melemo e meng e mengata. |

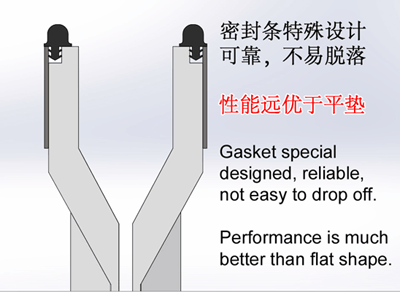

1. PE matrix + PTFE barbotage, e hloekileng holim'a filtration, ultra tlaase emission, e tsitsitseng ho hanyetsa.2.Lisebelisoa tse tala tse tsoang kantle ho naha, li netefatsa ts'ebetso e phahameng, athe khanyetso e tlase, 'me e hanana le botsofali.3.Hlooho ea filthara e siiloe kaofela, e nang le sebopeho sa mochini oa CNC, le matlafatso ea poleiti ea tšepe e sa hloekang, hlooho ea filthara e tiile ebile e otlolohile.4.Ring ea Gasket e entsoe ka mokhoa o ikhethileng, e kentsoeng ka har'a sekotjana sa ts'ebetso sa CNC, se ka tšeptjoang, se tšoarella, 'me ha ho na lebaka la ho tšoenyeha ka ho theoha.

5. Sefahla se ka tlase se lahleloa kaofela, se ka ba sa tiiso e ntle, e thata le e thata.

6. Boima bo ka tlase ho lik'hilograma tse 18, ho bonolo ho tsamaisa le ho boloka.

Jeremane e Qalile + Thepa e Rekiloeng ka Ntle ho Naha + Boqapi ba Theknoloji

E netefalitsoe ke laboratori ea Jeremane.

Lintlha tsa Tekheniki

Boholo ba Sefe

| Boholo | Sebaka sa Tlhophiso (m2) |

| HSL_1500 / 18 | 7.64 |

Sefa Mecha ea litaba

| Paramethara Mecha ea litaba Code | NT1 | AT1 |

| Katleho | 99.999% @ 1μm | |

| Opereishene Temp. | 70 ℃ | 70 ℃ |

| Ho Hloekisa Khatello ea Moea | 4.0 ~ 4.5 Bar | |

| Ho hanyetsa ho lutla ha motlakase | N/A | ≤ 106Ω |

| Karolelano ea A/C | 0.8~1.3 m/mots | |

| Ho hanyetsa Moea | 1500~2000 Pa (Ho ipapisitse le maemo a ts'ebetso) | |

| Mofuta oa ho kenya Ring ea Gasket | Khase e tala feela | |

* Ka kopo, bontša "Size + MediaKhoutu” ha o odara.

Mohlala: Sinter Plate Filter Element, Mofuta: HSL_1500/18 NT1.

Libaka tse sebetsang

| Indasteri ea tšepe | Nonferrous Metallurgy | Indasteri ea Likoloi | Ts'ebetso ea Ore | Indasteri ea Lithaere tsa Rubber |

| Indasteri ea Elektronike | Foundry | Laser-Cutting | Indasteri ea Lik'hemik'hale | Pharmacy |

| Phetoho ea Lijo | Indasteri ea Khalase le Ceramics | Indasteri ea Samente le Kalaka | Mosebetsi oa Tšepe | … |

-

Sinter Plate Filter Element (HSL1500/18)

Sinter Plate Filter Element (HSL1500/18)