Wholesale Delta2 - HSL type – Sinter Plate

Wholesale Delta2 - HSL type – Sinter Plate Detail:

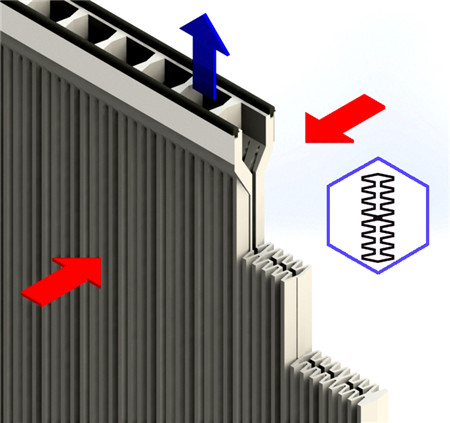

Sinter plate filter is a kind of shape stability and strong resistance to impact and load ability of filtering material. It is also called “plastic sinter plate”. The rigid filtering plate whose matrix is made of PE powder through special sinter process, and coated with PTFE (commonly known as “Plastic King”, the coating material of non stick pot). Due to pure surface filtration, it blocks the dust outside the filter material and is easily to be cleaned on line. It has a stronger filtration accuracy, which can be applied to various high or low temperature environments, and can be used repeatedly, effectively reducing the production cost.

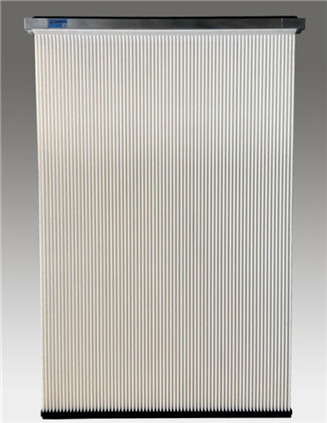

The Earlier Type of Sinter Plate Filter Element (For replacement):

HSL_1500/18

| So what is a sinter plate? The sinter plate here refers to rigid filtering plate whose matrix is made of PE powder through special sinter process, and coated with PTFE (commonly known as “Plastic King”, the coating material of non stick pot). Because the raw materials are all plastics, it is also called “plastic sinter plate”. This technology originated from Germany, and can make filters with various shapes.PTFE coating can block the dust outside the filter material, as the effect of “surface filtration”. This is quite different from the “deep filtration” effect of the fiber filter. At this point, only high-grade membraned filter media can be comparable to the sinter plate, but the coating of the sinter plate goes deep into the matrix, and is not easy to be worn and torn, and also many other advantages. |

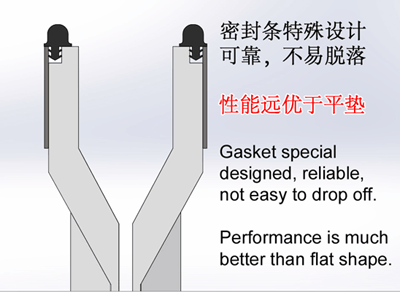

| 1. PE matrix +PTFE coating, pure surface filtration, ultra low emission, stable resistance.2. Imported raw materials, assure high efficiency, while low resistance, and wear-resist & aging-resist.3. Filter head is sintered all together, with CNC machined shape, and stainless steel plate reinforcement, the filter head is firm and straight.4. Gasket ring is specially designed, embeded in CNC formed installation slot, reliable, durable, and no need to worry about dropping off.

5. The filter bottom is cast in whole, which can be of good sealing, rigid and tough. 6. The weight is less than 18 kg, easy to move and maintain. |

|

Germany Originated + Imported Materials + Technology Innovation

Certified by German laboratory.

Filter Size

|

Size |

Filtration Area (m2) |

|

HSL_1500 / 18 |

7.64 |

Filter Media

| Parameter Media Code |

NT1 |

AT1 |

| Efficiency |

99.999% @ 1μm |

|

| Operation Temp. |

70℃ |

70℃ |

| Purging Air Pressure |

4.0~4.5 Bar |

|

| Electrostatic Leakage Resistance |

N/A |

≤ 106Ω |

| A/C Ratio |

0.8~1.3 m/min |

|

| Air Resistance |

1500~2000 Pa (Depends on operating conditions) |

|

| Gasket Ring Installation Type |

Raw Gas only |

|

* Please indicate “Size + Media Code” when ordering.

Example: Sinter Plate Filter Element, Type: HSL_1500/18 NT1.

| Steel Industry | Nonferrous Metallurgy | Automobile Industry | Ore Processing | Rubber Tyre Industry |

| Electronics Industry | Foundry | Laser-Cutting | Chemical Industry | Pharmacy |

| Food Processing | Glass and Ceramics Industry | Cement and Lime Industry | Metal Work | … |

Product detail pictures:

Related Product Guide:

Cooperation

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Wholesale Delta2 - HSL type – Sinter Plate , The product will supply to all over the world, such as: panama , Swaziland , Salt Lake City , Many kinds of different solutions are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of solutions with us!!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!