Isihluzi seCartridge-Sinter Plate-Sinter Plate Collector-Herding Sinter Plate Isihluzi-Sintered ipleyiti yesihluzi sentsimbi engatyiwayo

Inkcazo yeMveliso

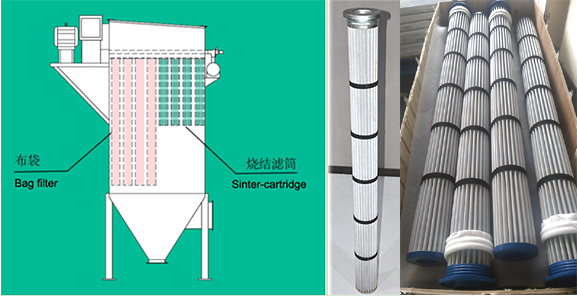

Ukudibanisa izixhobo eziguquguqukayo zetekhnoloji yokuhluza okomileyo kunye nezihluzi zengxowa: ii-Sinter Cartridges.I-PE (i-polyethylene) i-matrix ene-porous kunye ne-PTFE efakwe i-coating, i-filtration ecocekileyo yomhlaba, i-media-resistant plate filtration media media ene-wave-shaped cylindrical structure, enye indlela efanelekileyo kwiingxowa kunye ne-cage yayo. Ukusebenzisa i-bag filter, ineengxaki zokukhupha. ngaphezulu komgangatho, ukutsala umthamo womoya wehlile kwaye utshintsha ingxowa yelaphu rhoqo, njl.Ngokusebenzisa i-sinter cartridge elula kwaye kulula ukuyisebenzisa, kulula ukusombulula ezi ngxaki zinzima.

Kungakhathaliseki ukuba luthuli olune-abrasion eqinile, okanye uthuli oluphezulu, okanye imeko yokusebenza emanzi, i-cartridge ye-sinter iyakwazi ukuyiphatha ngokuzola.

Iimpawu/Izinto eziluncedo

Ukuphucula isihluzo sengxowa ngexabiso elincinci:

I-Sinter-Cartridge: I-LT Series

| Nciphisa ixesha lokuphumla.Nciphisa iindleko zokusebenza.Ukuhlangabezana nemigangatho yokukhupha.Ukwandisa umthamo wokuqokelela uthuli.Yandisa ubomi benkonzo yomqokeleli wothuli. |

| Ingaba isihluzo esidala sengxowa akukho lula ukusisebenzisa? | Ngaba isihluzo sakho sengxowa sikhupha ngaphezulu komgangatho?Ngaba umoya wokukhupha umoya wehlile kakhulu?Ngaba kufuneka utshintshe iibhegi zelaphu rhoqo? | Sikubonelela ngesisombululo esifanelekileyo, nge-sinter-cartridge elula kwaye kulula ukuyisebenzisa, ukusombulula iingxaki zakho ezinzima. |

| Indibaniselwano yenguqu iteknoloji yokuhluza okomileyo kunye nengxowa yokucoca: sinter-cartridge | I-PE porous matrix + i-PTFE efakelweyo yokwaleka, ukuhluzwa okucocekileyo komphezulu, ukusebenza kakuhle kunye nemithombo yeendaba yokucoca i-sintered enganxitywayo, enesakhiwo sesilinda esimiliselwe ngamaza, ibuyisela ngokugqibeleleyo ingxowa yelaphu kunye nekheji; | 99.999% ukusebenza kakuhle.Ukujongana ne-0.1um particle.Emission <<1mg / Nm3Self lubricating kunye hydrophobic imathiriyeli, kulula purgeNo fiber |

| Uphuculo olubonakalayo kwiinkonzoubomi kunye nokusebenza kakuhle | Kungakhathaliseki ukuba luthuli olune-abrasion eqinile, okanye uthuli oluphezulu, okanye imeko yokusebenza emanzi, i-cartridge ye-sinter iyakwazi ukuyiphatha ngokuzola. | I-sinter-cartridge eyenziwe ngemithombo yeendaba ephuculweyo ene-sintered, enokuhluza okuphezulu, ixesha lokuphila lenkonzo elingaphezulu kweminyaka eli-10, kunye nokusebenza okungaguqukiyo kokucoca. |

| Iindleko eziphantsi, ngokukhawuleza kwaye kulula | Khetha i-sinter-cartridge kwaye ubeke indawo yokucoca ingxowa ngokuthe ngqo ngaphandle kokutshintsha isakhiwo somqokeleli wothuli wokuqala. | Ukunciphisa ixesha lokuphumla, ukwandisa ubomi benkonzo yomqokeleli wothuli. |

Idatha yoBugcisa

Ubungakanani besihluzi

| Ubungakanani | Indawo yoHluzo (m2) |

| LT125-1500 | 1.49 |

| LT125-750 | 0.73 |

| LT125-500 | 0.48 |

| * LT133-1500 | 1.62 |

| * LT133-750 | 0.80 |

| * LT133-500 | 0.53 |

| LT162-1500 | 2.03 |

| LT162-750 | 1.00 |

| LT162-500 | 0.66 |

* Uhlobo olucetyiswayo.(Olunye uhlobo olungekho kuluhlu lunokwenziwa ngokwezifiso.)

Isihluzi semidiya

| Ipharamitha Ikhowudi yemidiya | NT1 | AT1 | NT2 | AT2 |

| Ukusebenza kakuhle: 99.999% @ 1μm | ● | ● | ● | ● |

| Ukusebenza kweTemp. | 70℃ | 70℃ | 100℃ | 100℃ |

| Ukunyangwa kokuvuza kwe-Electrostatic | N / A | ≤ 106Ω | N / A | ≤ 106Ω |

| A/C Umlinganiselo | 0.8-1.3 m/m | |||

| Ukumelana nomoya | 1500~2000 Pa (Kuxhomekeke kwiimeko zokusebenza) | |||

| Uhlobo loFakelo lweGasket Ring | IGesi ecocekileyo | |||

* Nceda ubonise “Ubungakanani + MediaIkhowudi” xa uodola.

Umzekelo: I-Sinter-cartridge, Uhlobo: LT133-1500 NT1.

Imimandla Esebenzayo

| Ishishini lentsimbi | I-Metallurgy engasebenziyo | Ushishino lweemoto | Ukwenziwa kweOre | Rubber Tire Industry |

| Ishishini le-Electronics | Foundry | Laser-Cutting | Ishishini leMichiza | Ikhemesti |

| Ukulungiswa kokutya | Imveliso yeglasi kunye neCeramics | Ishishini leSamente kunye neLime | Umsebenzi Wesinyithi | … |

-

Isihluzi seSinter-Cartridge Element (LT Series)

Isihluzi seSinter-Cartridge Element (LT Series)